dutchland foods blog

Exciting news! We are thrilled to announce the launch of our brand new web page dedicated exclusively to the pastry of the summer: The Filled Kouign Amann!

Our Filled Kouign Amann is a revolutionary take on the classic French pastry, offering a delightful array of fillings that elevate the traditional experience to new heights. From the rich sweetness of cinnamon to the tartness of blueberry cream cheese, our filled variations are sure to excite taste buds and leave a lasting impression.

But that’s not all. On our dedicated web page, you’ll find everything you need to know about this irresistible treat. From detailed product descriptions to mouthwatering images, we’ve curated an experience that captures the essence of our Filled Kouign Amann.

Ready to take the next step? Simply visit our web page to access the One PageSell sheet for this product, where you can find all the essential details for incorporating it into your lineup. Plus, if you’re interested in working with us, you can inquire directly through the page or by reaching out to us via email at sales@dutchlandfoods.com.

Still wondering if adding the Filled Kouign Amann to your product list is the right move? Let our clients speak for themselves:

“The Kouign Amann pastry has been a welcome addition to our pastry program at CC’s Coffee House. It’s an incredibly dynamic product that is perfect with rich sweet cinnamon filling all the way to a tart blueberry cream cheese filling. Both of those flavor profiles have been instrumental in our LTO campaigns for Winter and Spring. We are proud to offer our guests this product in the neighborhoods in which we serve and look forward to new and exciting ways to offer it for future campaigns.” – David Hooper (CC’s Coffee)

Don’t miss out on the opportunity to elevate your offerings with the hottest pastry on the market. Visit our web page today and discover why Filled Kouign Amann is the perfect addition to your product lineup!

Happy Baking!

We wanted to take a moment to applaud our Food Safety Team, and all their hard work that led up to achieving our latest score of a BRC AA+ Rating! In light of this recent milestone, we took some time to interview Sarah Warner, Manager of our Food Safety Personnel here at Dutchland Foods.

Can you provide an overview of Dutchland Foods’ approach to food safety and quality assurance?

All day, every day! We approach with a team effort and a mindset that every employee shares food safety responsibility.

Can you give an example of a specific measure we take to ensure the safety and integrity of its food products?

Allergen control. Products must contain only the allergens listed in the product, so we take careful measures at every step of our process to ensure that this is the case.

How do we stay up-to-date with industry standards and regulations related to food safety?

The FS team has enrolled in many industry email lists that keep us updated with regulations, including FDA & USDA emails. We also learn through webinars, customers, and auditors. The BRC guidelines themselves help us to stay up to date with regulations and standards.

What role does the BRC Global Standards play in Dutchland Foods’ Day to day operations?

The BRCGS provides guidelines for our food safety systems, setting a standard for everything from maintenance controls to sanitation programs to manufacturing & quality processes. The standards also align with FDA regulations.

Can you explain the process Dutchland Foods went through to achieve the BRC AA+ Food Safety rating?

Every day we work to comply with the standards to maintain the safest & highest quality of product possible. Preparation is key!

The “+” in the rating is because the audit was unannounced. We knew the auditor was coming sometime in a four-month window, but we didn’t know when! The audit was 2.5 days long and included a physical plant inspection and procedure/paperwork review.

What are some of the key criteria or requirements we have had to meet to attain the BRC AA+ rating?

Supplier management, HACCP, sanitation, allergen control, GMPs for employees (Good Manufacturing Practices), maintenance programs, temperature controls, metal detection, pest control, chemical control, employee training, product weight controls, process controls, food safety culture, to name a few – every step of the food process is affected by food safety!

How does achieving the BRC AA+ rating benefit Dutchland Foods and its customers?

It provides assurance that our food is high quality and safe and that we are a supplier that can be trusted.

Can you highlight any specific initiatives or investments we made to enhance its food safety practices?

We have recently purchased new state-of-the art equipment, including a new mixer, line, attachments, and spiral proofer and freezer, that all enhance the safety of the product that we produce.

What sets Dutchland Foods apart from other food manufacturers in terms of food safety and quality?

We have highly motivated employees with strong work ethics that keep things moving! Management is also willing to invest in the company to uphold our food safety and quality standards.

How do we prioritize continuous improvement in its food safety practices?

Every quarter a trained group of employees audits one section of the BRC standards to identify potential areas for improvement. We approach with a team effort.

Can you tell us a little about the Food Safety Team, and what this accomplishment means to you?

The Food Safety Team consists of five dedicated employees. We work hard but also have fun. It is very satisfying that all our hard work has paid off, but we know food safety takes continual effort!

Welcome back to our blog, where we take you behind the scenes to showcase the incredible team that powers Dutchland Foods. Today, we’re not just focusing on an individual, but celebrating our entire maintenance crew, a vital engine in our quest to deliver exceptional pastries.

The Unsung Heroes of Dutchland

Our maintenance crew is the backbone of our operations. They’re the problem-solvers, the fixers, the creators who ensure everything runs smoothly. From routine checks to emergency repairs, their work is crucial in preventing downtime and ensuring that our production line is efficient, and our pastries are of the highest quality.

Innovation at Its Best

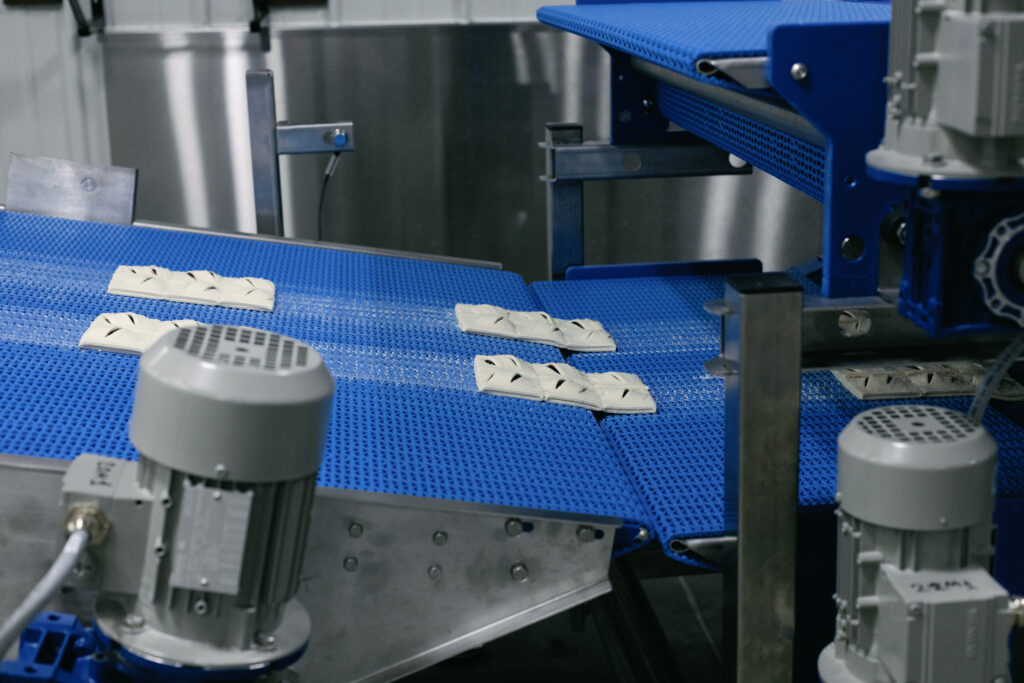

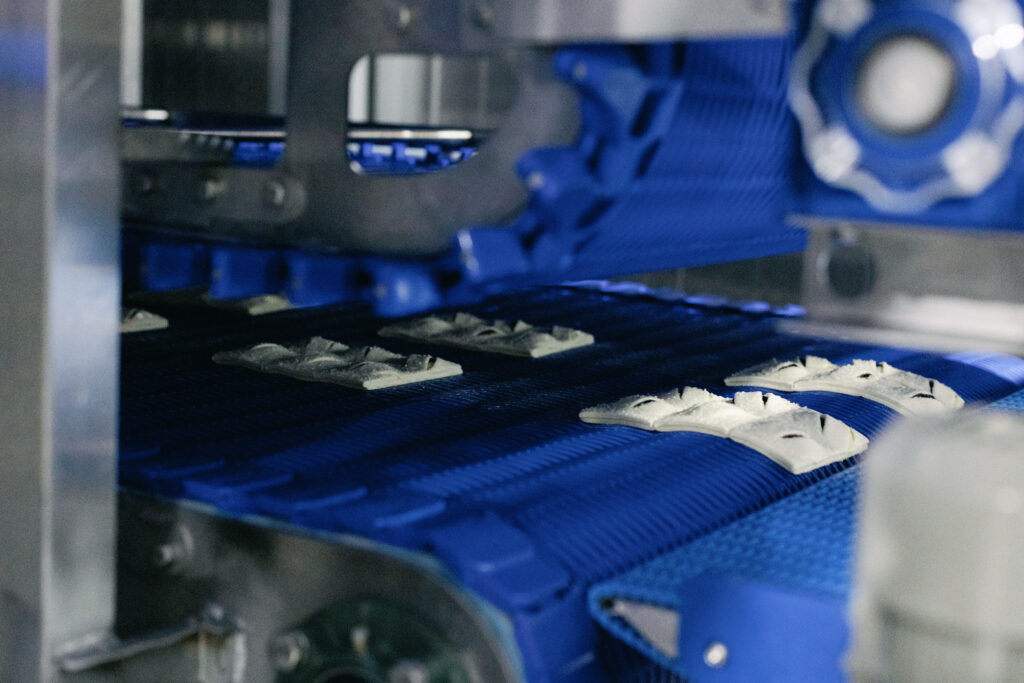

Innovation is at the heart of what we do, and our maintenance team plays a pivotal role in this. Whether it’s designing custom tools to create unique pastries or developing new equipment to enhance our processes, their creativity knows no bounds. An example of their ingenuity is a custom guillotine blade with wipers, designed to keep the dough from sticking, thereby improving the efficiency of our pastry cutting process.

Collaboration and Efficiency

Our maintenance crew’s work extends beyond repairs and innovations. They collaborate closely with all departments, ensuring that the equipment and tools they create or maintain meet the specific needs of each team. This synergy is essential for our bakery’s productivity and helps us continually refine our processes to deliver the best possible products to our customers.

A Culture of Continuous Improvement

The ethos of our maintenance team is one of continuous improvement. They’re always on the lookout for ways to enhance our operations, whether it’s through faster repairs, innovative tools, or more efficient processes. Their dedication not only impacts our bottom line but also ensures that we can keep our promise to our customers to provide unique and high-quality pastries.

Celebrating Teamwork

Together, our maintenance crew exemplify teamwork, innovation, and pursuit of excellence. Their collective efforts surely speak to our company’s commitment to quality and innovation.

In Conclusion

As we celebrate our maintenance crew, we’re reminded of the importance of every role at Dutchland. It’s their behind-the-scenes work that allows us to shine and continue to bring joy to our customers through our pastries. So, here’s to our maintenance team – the unsung heroes who are essential to our success.

Stay tuned for more stories from behind the scenes, where we’ll continue to highlight the people and processes that make Dutchland Foods special. Thank you for joining us on this journey, and here’s to the many hands that contribute to our achievements!

At Dutchland Foods, we’re always on the lookout for ways to make our pastries the highest quality they can be, and our production processes smoother than ever. That’s why we recently welcomed two amazing guests: Thierry Reboullet from France and Wiep Bergsma all the way from The Netherlands.

Why Did Dutchland Decide to Bring Them In?

Thierry and Wiep came for different reasons, but both were super important! Wiep, the tech whiz from Rademaker, traveled across the ocean to help us launch our new makeup line smoothly. Think of him as the pastry guru who knows how to make the flakiest pastries at any scale! Meanwhile, Thierry, from the land of croissants and gourmet delights, joined us to tweak our fillings and work on a cool new project.

Tackling Challenges and Goals

We had some big goals in mind when we flew them in. Wiep jumped in to make sure all our products smoothly transitioned to the new makeup line, training our team as he went. Thierry focused on perfecting our fillings and helping out with a special project we’ve got cooking.

Perfect Match for Dutchland’s Goals

Thierry and Wiep’s skills fit like a glove with what we’re all about at Dutchland. Wiep knows his way around pastry-making equipment like nobody’s business, and Thierry’s got years of experience making mouthwatering fillings. They’re both all about making top-notch pastries efficiently.

Teamwork Makes the Dream Work

Our collaboration with Thierry and Wiep was all about teamwork. Wiep dove right into the nitty-gritty with our production crew, showing them the ropes of the new equipment. Meanwhile, Thierry teamed up with our R&D pros to tweak our fillings and formulas.

Instant Improvements and Smart Tweaks

Thanks to Thierry and Wiep’s genius ideas, we saw quick improvements in our production. Wiep’s tweaks to our dough process and Thierry’s focus on temperature control for fillings made a big difference right away.

Setting Up for Success

Having Thierry from France and Wiep all the way from The Netherlands around wasn’t just about fixing things up now—it’s about setting ourselves up for success in the long run. With their help, we’re better equipped to take on whatever challenges come our way and keep making the tastiest pastries around.

In a nutshell, our pastry adventure with Thierry Reboullet and Wiep Bergsma wasn’t just a visit—it was a recipe for success! Their skills and know-how have helped us level up our pastry game and keep moving forward towards our goal of pastry perfection.

Within the world of pastry innovation, Dutchland Foods sets a high bar of culinary craftsmanship. At that heart of our commitment to creating excellent pastries lies Our Research & Development Team. In this blog post, we delve into the fascinating journey of how this dedicated team bring exciting and unique pastries from concept to reality, catering specifically to the discerning tastes of Private Label Buyers.

The Pastry Request:

It all begins with a simple pastry request. Whether it’s a classic Danish, a flaky croissant, or a unique twist on an old favorite, Our lead R&D Specialist Faith and her team are ready to take on the challenge. When a request lands on their desks, the excitement of creating something extraordinary ignites their passion.

Research and Recipe Development:

The first step in this culinary adventure is research. Faith scours through centuries-old recipes, modern trends, and international influences to gather inspiration. Her mission is to craft a pastry that not only meets but exceeds the expectations of our Private Label Buyers.

Once inspired, it’s time to get hands-on. The team starts experimenting, creating different versions of the pastry until they get it as close to perfection as possible. Every ingredient is meticulously chosen for taste and quality, ensuring that every bite is a delightful experience.

Collaboration with Production Team:

Creating an exceptional pastry isn’t just about flavor; it’s also about feasibility. Faith and her team collaborate closely with our production team to assess if the concept can be realistically produced on a mass scale. This partnership ensures that the vision aligns seamlessly with the practicalities of large-scale production.

Private Label Buyer Feedback:

With a prototype in hand, it’s time to send it to our clients for feedback and approval. Their valuable insights and discerning tastes guide us toward perfection. Every comment, suggestion, and critique is invaluable, propelling us toward the ultimate goal of delivering a pastry that exceeds expectations.

Fine-Tuning and Perfection:

After receiving feedback, Faith and her team go back to the drawing board, making meticulous tweaks to ensure that every aspect of the pastry meets the highest standards. The process can be repetitive, but it’s this commitment to excellence that sets Dutchland Foods apart from the competition. Remarkably, this entire process, from initial concept to a pastry ready for mass production, can be accomplished in just around 8 weeks. Dutchland Foods takes pride in its agility and efficiency in bringing new culinary delights to market.

At Dutchland Foods, we take you on a smooth and carefully planned journey from the idea stage to your plate. It’s a process filled with creativity, new ideas, and hard work. We welcome Private Label Buyers to discover our world, where each pastry is a carefully crafted work of art made with attention and a strong commitment to going beyond what you expect. Come and experience this delightful adventure with us and savor the difference for yourself.

Hello dear patrons, partners, and friends,

We wanted to take a moment to reflect on our Open House on August 26th, and more importantly, to express our gratitude.

First and foremost, thank you to each and every one of you who took time out of your busy schedules to join us. Your enthusiasm and support were obvious, and it truly made the event special. We were thrilled to see familiar faces, meet new ones, and share a day that was all about celebrating our accomplishments, blessings, our history, and our future.

The tour of the facility was an incredible experience, not just for our guests but for us as well. Being able to show you firsthand where everything happens, and to share our passion for the processes behind our pastries was truly an honor.

Through our history video, we took a nostalgic journey together, tracing the roots of Dutchland Foods and reminiscing the milestones that have brought us to where we are today. Your positive feedback on the video was heartwarming, and we’re glad to have captured the essence of our journey in a way that resonates with all.

And of course, what’s a gathering without some delightful food? The catered lunch was a hit, and we hope you enjoyed the flavors as much as we enjoyed presenting them to you. It was a wonderful time of fellowship, laughter, and creating memories.

Last but by no means least, a special acknowledgment is due to our sponsors. While we will provide a detailed list of them towards the end, we want to say this now: Your support and belief in Dutchland Foods not only made this event possible but has been instrumental in our journey. A massive thank you is in store.

In closing, the Open House was not just an event; it was a testament to the bond we share with our community, our partners, and our patrons. Here’s to many more years of togetherness, growth, and shared success.

Until next time, Happy Baking!

Warm regards, Dutchland Foods

Northland Siding

AB Window Coverings

People’s Bank

Lyon County Pork Producers

Hey there, food enthusiasts! I’ve got some exciting news to share from our very own Dutchland Foods. Brace yourselves for the latest game-changer in food production: our cutting-edge spiral proofer and freezer! This revolutionary proofer and freezer is all about taking our local food scene to new heights, with enhanced efficiency and top-notch product quality.

Efficient Proofing and Freezing with Spiral Technology: Spiral freezers rapidly freeze food products using a continuous spiral conveyor belt system. This process ensures even freezing, resulting in superior product quality. Dutchland Foods’ new spiral freezer takes this technology to the next level, enabling faster freezing cycles and enhanced efficiency.

Advantages for Food Production:

- Versatility: Spiral proofers and freezers can be used for freezing, dehydrating, and cooling various food products, making them a practical choice for food processors.

- Space-Saving Design: Dutchland Foods’ spiral proofer and freezer requires minimal floor space, making it suitable for compact production facilities.

- Customization: The proofer / freezer offers adjustable conveyor speeds and temperature settings, allowing for tailored freezing and cooling processes based on specific production needs.

- Hygiene and Cleanliness: The touch-free operation and germ-free cold airflow of the spiral freezer ensure high levels of hygiene, making it ideal for food processing applications.

Get ready to embark on a flavor-filled journey, my friends! Dutchland Foods’ revolutionary spiral proofer and freezer is set to redefine our local food production. With its lightning-fast freezing, space-saving design, and customizable features, it’s a true game-changer. Our local producers can now create exceptional food products while meeting the highest standards of efficiency and quality. So, let’s celebrate this exciting leap forward in food production and savor the delicious results Dutchland Foods’ spiral proofer and freezer brings to our plates.

What if you had a secret weapon that was not only delightfully delicious but also exclusive, easy to prepare, and offered great profit margins for your next Fundraiser? Enter the Pastry Puffins and ButterHearts from Dutchland Foods – your secret weapon to fundraising success!

Let’s look at why these pastries should be your go-to for your next fundraiser:

1. Exclusivity That Creates Demand

What makes Pastry Puffins and ButterHearts so special? They are exclusive to the fundraising market. You won’t find these delicacies on retail shelves, which creates a demand that boosts sales during fundraising events. People buy in bulk, eager to stock up on their favorite pastries while they have the chance.

2. Convenience is Key

Pastry Puffins and ButterHearts are the epitome of convenience. No need to thaw or prep these goodies. They go straight from the freezer to the oven, making them a perfect fit for busy families and hectic event schedules.

3. Profitable and Practical

Apart from being irresistibly tasty, these pastries offer impressive profit margins for your organization. With an average group profit margin of 40%, Pastry Puffins and ButterHearts aren’t just a sweet treat – they’re a smart financial choice for your fundraiser.

4. All-Season All-Stars

While these pastries are a year-round hit, they’re particularly popular during the fall, winter, and spring seasons. Plus, they’re a must-have during holiday festivities. The delightful aroma of baking pastries is sure to draw a crowd!

5. Customer Support You Can Count On

Dutchland Foods connects eager customers with our trusted Dealers who can link them with active fundraisers. It’s a win-win situation: customers get their favorite pastries, and schools, churches, and organizations see their fundraising profits soar.

So, when planning your next fundraiser, consider the delicious and unique offerings of Pastry Puffins and ButterHearts from Dutchland Foods. They’re not just pastries – they’re a strategic choice for successful fundraising.

Looking to add these crowd-pleasing pastries to your fundraising line-up? Reach out to us at Dutchland Foods, and we’ll help you get started on your journey to a successful, and delicious, fundraiser.

Imagine this: the irresistible smell of pastries baking, the sound of an oven timer dinging, and the sight of golden, delicious treats ready to be devoured. Now imagine all this delight could help your school, church, or organization raise some serious dough. Too good to be true? Not with Dutchland Foods!

At Dutchland Foods, we’ve concocted a sweet recipe for fundraising success with our exclusive delights, Pastry Puffins and ButterHearts. These pastries aren’t your run-of-the-mill, find-’em-in-any-grocery-store kind of treat. Oh no, they’re fundraising superstars!

Here’s the scoop: these pastries are so special you can’t find them in retail stores. Talk about an exclusive VIP (Very Important Pastry) experience! This exclusivity creates a pastry frenzy during fundraising events as folks clamor to stock up while they can. It’s like the pastry equivalent of a doorbuster sale on Black Friday!

What makes these pastries even cooler is their ease of use. No thawing, no prep, just straight from your freezer to your oven. It’s as easy as pie… or should we say, as easy as Pastry Puffins and ButterHearts!

Our mailbox at Dutchland Foods is overflowing with requests from pastry aficionados wanting more. So, we act as a sort of pastry matchmaker, connecting eager customers with our trusted Dealers who then link them with active fundraisers. It’s like a baking version of a rom-com, where everyone gets their happily ever after, and the hero is a scrumptious pastry!

Here’s some more delicious news: these pastries aren’t just about pleasing your taste buds. They’re also about filling up your fundraising pot. With an impressive 40% profit margin for the average group, our pastries are more than just tasty – they’re a strategic choice for your fundraiser.

While these delightful pastries are a hit all year round, they turn into celebrities during the fall, winter, and spring seasons, especially during holiday festivities. Who wouldn’t want their house filled with the heavenly aroma of baking pastries during the holidays?

So, are you ready to add a fun, tasty twist to your fundraising efforts? Crank up the oven and get ready to bring in some serious funds with Dutchland Foods’ Pastry Puffins and ButterHearts. It’s not just about selling pastries; it’s about providing a unique experience that people can’t wait to be part of, all while contributing to a good cause.

Hey pastry fans, have you tried a Bear Claw Croissant? This sweet and flaky puff pastry has been a hit for over a hundred years! It all started with Austrian bakers who got inspired by the shape of a bear’s paw and called it “Bärentatze.” It’s made of a soft, yeasty dough filled with almond paste and sliced almonds.

In the USA, the Bear Claw Croissant is a popular spin-off that combines the classic bear claw flavors with the buttery, flaky texture of a croissant. It’s a mouthwatering mix of cultural traditions and deliciousness!

The Bear Claw is typically made with a tender and flavorful dough with an almond-flour based filling. However, for a softer texture, some bakers recommend using almond paste instead. Once the filling is in place, the pastry is topped with sugar and slivered almonds for a touch of sweetness.

Bear Claws can be made with a variety of fillings, such as cinnamon, cherry, apple, or cream cheese. At Dutchland Foods, we take pride in honoring the tradition of the Bear Claw Croissant by crafting each pastry with care, making sure it has the classic semi-circle shape and curved edge. We believe that food is not just about eating, it’s also about celebrating culture, tradition, and creativity.

So whether you’re a chef who wants to offer something unique to your customers or just a pastry lover in search of new flavors, come try the Bear Claw Croissant and experience the magic of culinary innovation and creativity!